Door Removal, Panel Removal, Panel Installation, & Roof Vent Removal - Part 3

/As we mentioned in part 1, we had a lot of working going on the last couple days! Here’s what was on the docket:

New Panel Installation (finally finishing it) (Part 3)

Beginning Roof Vent Removal (Part 4)

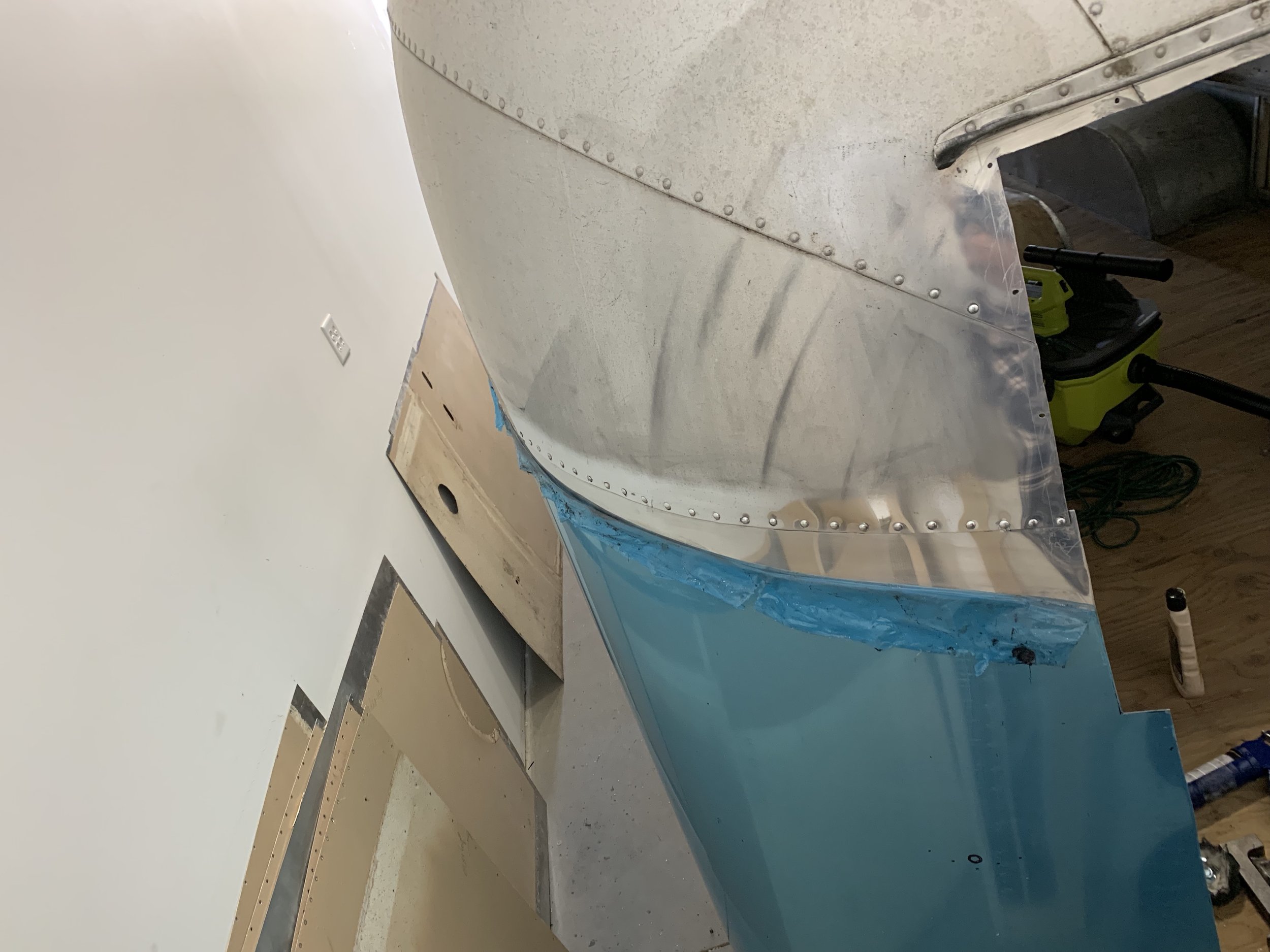

Today we’ll talk about the new panel installation! We wrapped up our rear lower street-side panel installation finally! We had it tacked in for a long time but hadn’t finished the buck riveting and getting everything aligned. Well we finally did it. I don’t know what the problem is with some of these things. I hope someone that’s reading this can sympathize. When I work through something in my head and I can’t quite feel comfortable with the process, I have a hard time finishing something up until I can get my mind completely wrapped around it. This time it was with this panel.

We got all the buck rivets and the sealant/adhesive on the top all into place and set and I couldn’t wrap my head around getting the bottom all straight while keeping the panel from bucking while also following the contour of the rear corner. Well, it all worked out just fine. We tacked in the bottom of the panel in the gap where the rear panel will go eventually, and tightened up the bottom as tight as we could go. Then we made sure that the top of the panel was straight and aligned. Drill a couple holes, plug in some clecos and voila! we’ve got a panel aligned. The last stage was to get the buck rivets in at the top and cleco in the bottom to the bottom C-channel.

All in all it turned out perfectly. I’m super happy that the dents and crumples are gone and we have a new shiny panel all in place. I should probably not stress out so much about it being perfect.

More tomorrow about the roof vent replacements. More to come on the rear panel in place as well!